Leading Provider of Automatic Weighing Equipment

Leading Provider of Automatic Weighing Equipment

Multi-head weighers are advanced weighing machines that can accurately weigh and package a wide variety of products, such as snacks, confectionery, and frozen foods, at high speeds. They are commonly used in the food industry and other manufacturing industries where precise and efficient weighing is essential.

One of the key features of multi-head weighers is their ability to calculate combinations of different weights to achieve the target weight for each package. In this article, we will explore how multi-head weighers calculate combinations and why it is important for efficient and accurate weighing.

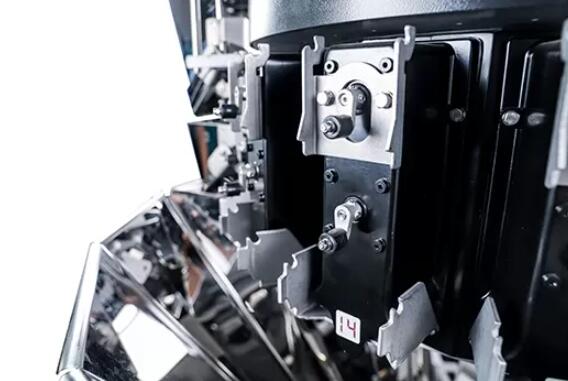

A multi-head weigher typically consists of a hopper, a feeder, and several weighing buckets or heads. The product is fed into the hopper, which then distributes it evenly to the feeder. The feeder drops the product into the weighing buckets, which are individually controlled by load cells that measure the weight of each bucket.

The multi-head weigher uses advanced software to calculate the combination of weights needed to achieve the target weight for each package. The software takes into account various factors, such as the weight of the product, the number of heads, the target weight, and the product flow rate.

The software also takes into account the distribution of the product within each head. This is because the product may not be evenly distributed within each head, which can affect the accuracy of the weighing. To overcome this, the software can adjust the combination of weights to compensate for any uneven distribution.

Combinational weighing is important for several reasons. Firstly, it allows multi-head weighers to achieve high levels of accuracy and consistency in weighing. By calculating the combination of weights needed for each package, multi-head weighers can ensure that each package contains the correct amount of product, even if the individual weights vary slightly.

Secondly, combinational weighing allows multi-head weighers to achieve high speeds while maintaining accuracy. By weighing multiple heads simultaneously and calculating the combination of weights in real-time, multi-head weighers can achieve speeds of up to 120 packages per minute.

Thirdly, combinational weighing allows multi-head weighers to handle a wide variety of products with different shapes, sizes, and densities. By calculating the combination of weights needed for each product, multi-head weighers can ensure that each package is filled to the correct level, regardless of the product's characteristics.

Multi-head weighers are advanced weighing machines that can accurately weigh and package a wide variety of products at high speeds. Combinational weighing is a key feature of multi-head weighers that allows them to achieve high levels of accuracy and consistency in weighing, handle a wide variety of products, and achieve high speeds while maintaining accuracy.

By using advanced software to calculate the combination of weights needed for each package, multi-head weighers can ensure that each package contains the correct amount of product, even if the individual weights vary slightly. This makes them an essential tool for the food industry and other manufacturing industries where precise and efficient weighing is essential. We are a multi-head weigher supplier. If you are interested in our products, please contact us now!